HP GRAPHITE ELECTRODES

hiddenValue

- Description

- Technical Data

-

Overview:

HP GRAPHITE ELECTRODES – the Diameters Range From 200 mm to 600 mm

HP graphite electrode is mainly used for high power electric arc furnaces with the current density range of 18–25 A/cm2.

Description:

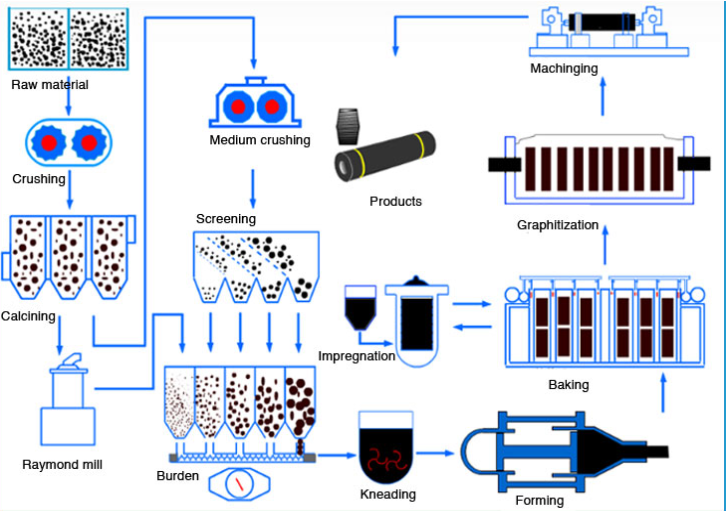

HP graphite electrode is the conducting element for electric arc furnaces steelmaking. It is made of petroleum coke, needle coke, coal pitch and produced by a series of strict production processes. High-current lines insert through the graphite electrode port inside the furnace body. This will releases electric energy in the arc furnace to heat the furnace.

The demand for the larger diameter electrodes has been increasing as EAF furnace sizes become larger. Graphite electrodes with diameter of 500 mm or 600 mm have become increasingly popular in recent years.

Features:

- Anti-oxidation treatment for longevity;

- High-purity, high-density, strong chemical stability;

- High machining accuracy, good surface finishing;

- High mechanical strength, low electrical resistance;

- Resistant to cracking & spalling;

- High resistance to oxidation and thermal shock.

Applications:

Graphite electrodes are widely used for production of alloy steels, metal and other nonmetallic materials, etc.

DC electric arc furnace.

AC electric arc furnace.

Submerged arc furnace.

HP Graphite Electrode is a high-performance graphite electrode used in electric arc furnaces for the production of steel and other metals. The HP in its name stands for High Power, indicating its high current-carrying capacity and thermal conductivity. The HP Graphite Electrode is made of high-quality petroleum coke, needle coke, and coal tar pitch, which are mixed and molded into a cylindrical shape under high pressure. The resulting graphite electrode can withstand extreme heat and electrical stress, making it capable of operating at higher temperatures and producing more steel per unit time than other electrodes. The HP Graphite Electrode features low electrical resistance, high thermal conductivity, and excellent mechanical strength, ensuring stable and efficient performance during the steelmaking process. The use of HP Graphite Electrodes not only enhances productivity but also reduces energy consumption, thereby reducing the overall cost of steel production. The HP Graphite Electrode is an essential component in electric arc furnace steelmaking and is widely used in various industries, including steelmaking, chemical, and metallurgy.

Spec:

Nominal Diameter Resistivity Density Flexure Strength Elastic Modulus Ash Content CTE Current Load Current Density (mm) (in) (≤, µΩ·m) (≥,g/cm 3) (≥,MPa) (≤, GPa) (≤, %) (100 °C – 600 °C) (A) (A/c㎡) 300 12 6 1.67-1.73 12 10.5 0.3 2 13000-17400 17-24 350 14 6 1.67-1.73 12 10.5 0.3 2 17400-24000 17-24 400 16 6 1.67-1.73 12 10.5 0.3 2 21000-31000 16-24 450 18 6 1.67-1.73 12 10.5 0.3 2 25000-40000 15-24 500 20 6 1.67-1.73 12 10.5 0.3 2 30000-48000 15-24 550 22 6 1.67-1.73 12 10.5 0.3 2 34000-53000 14-22 600 24 6 1.67-1.73 12 10.5 0.3 2 38000-58000 13-21 650 26 6.2 1.67-1.73 12 10.5 0.3 2 41000-65000 12-20 700 28 6.2 1.67-1.73 12 10.5 0.3 2 45000-72000 12-19

Keywords:

Keywords:- Graphite Electrode

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Related Product